INGEO

OPTIMIZED GEOMETRY FOR CO2 ABSORPTION - IAAC

TARGET - TO DEVELOP A PERFORMATIVE MATERIAL SYSTEM THAT CAN ABSORB AND REDUCE CO2 POLLUTION

Ingeo is a material system of modified Ion-Exchange Resin (IER) and its CO2 absorbing capabilities which can be utilized as a performative architectural skin. Originally developed by Klaus Lacker from Arizona State University, Lackner claims [the resin specializes] in carbon dioxide collection and [is] about 1,000 times faster than natural trees.” After rigorous testing, we developed a coatable IER solution that can be applied to optimized surface geometry and be utilized architecturally in highly concentrated areas ie. cities. By developing geometrically optimized panels coated with our solution, we proposed for them to be applied to building facades or interior office walls to act as CO2 combs and drastically improve air conditions. - video link.

Project Team: Olivia Alvarez - Design / Research / Fabrication / Photogarphy / Presentation / Research paper | Anton Koshelev - Grasshopper - 3D model / Arduino | Ivan Marchuk - Design / Research / Architectual Proposals / Renders

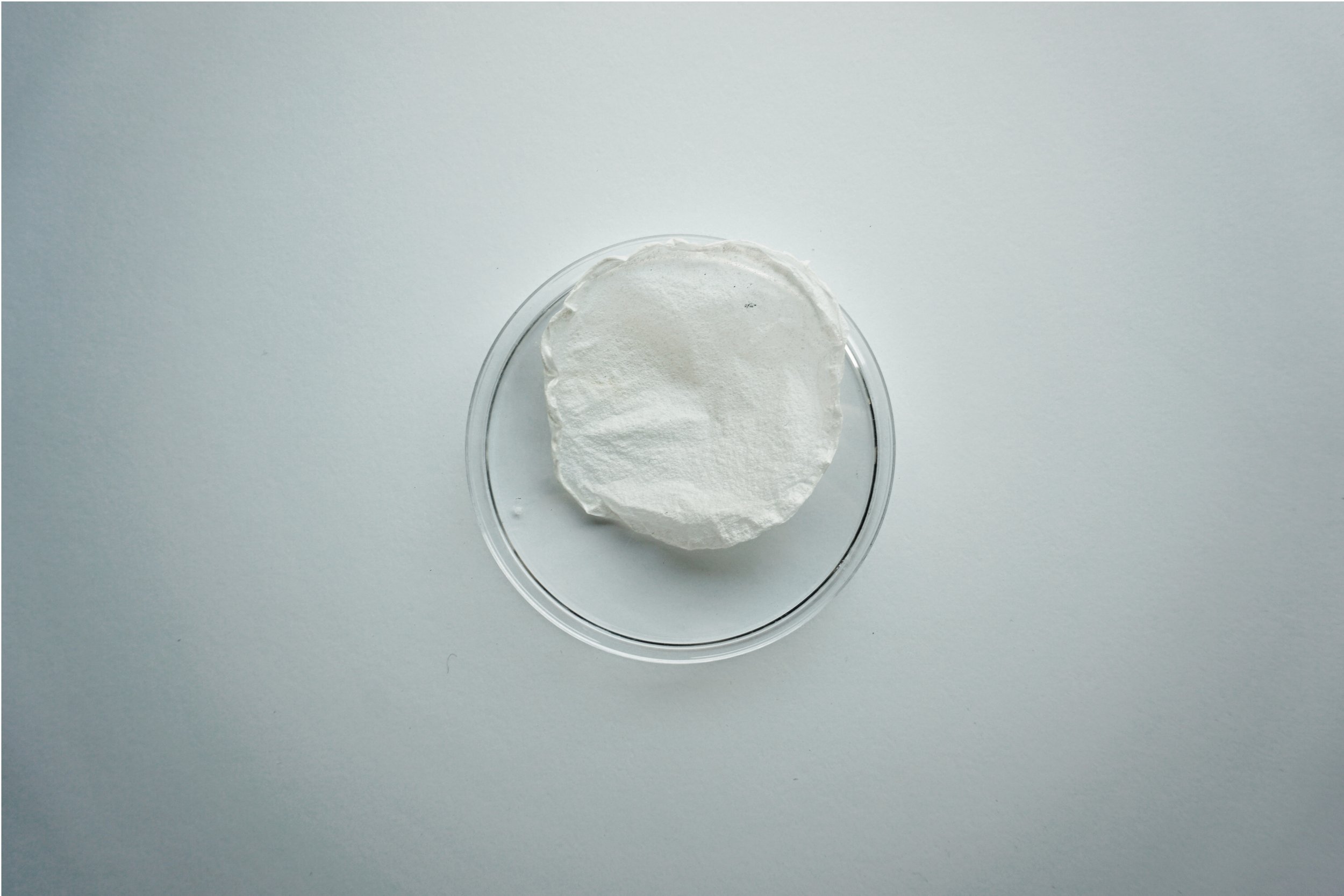

ASA-based polymer film

ABS-based polymer film

PVC-based polymer film

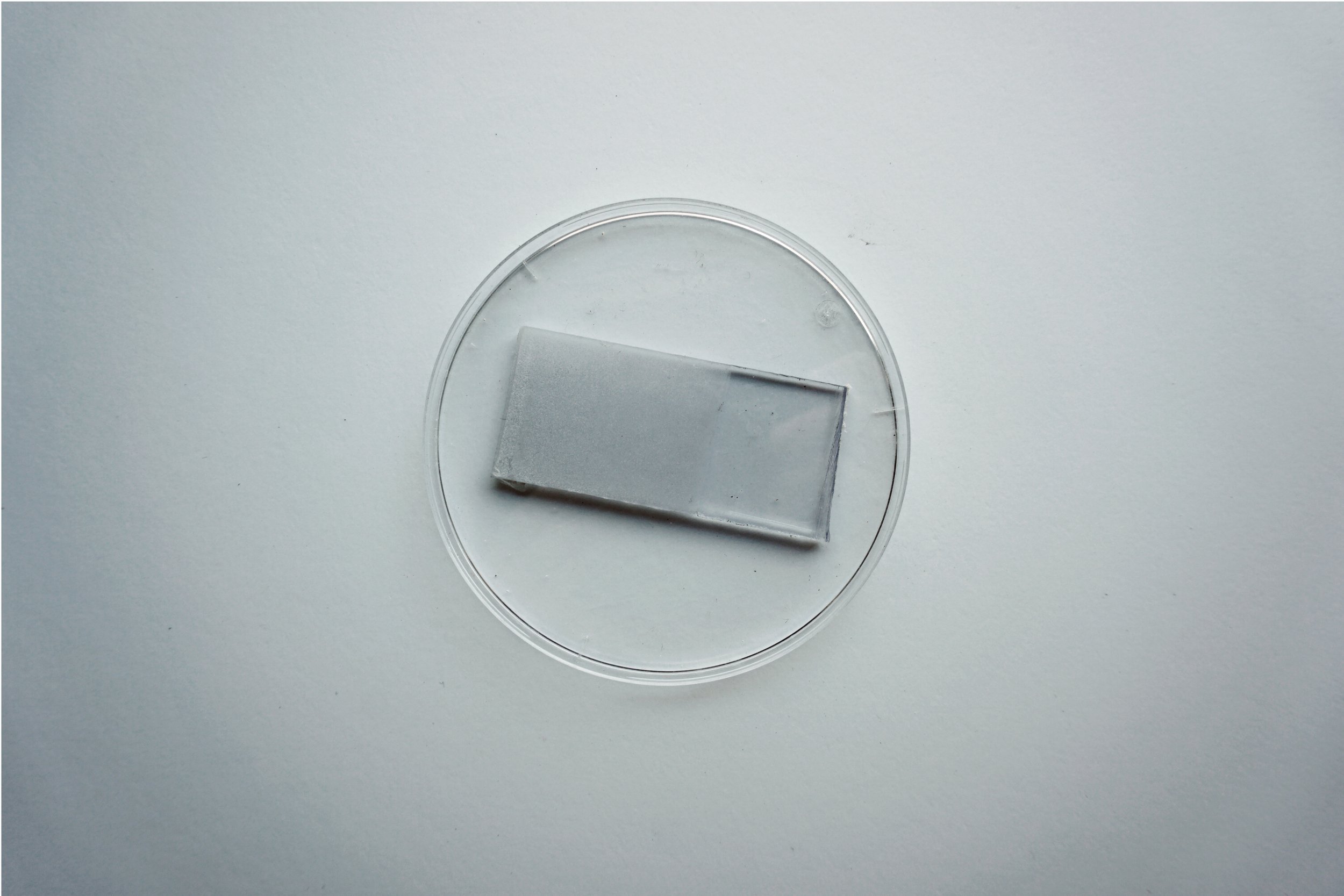

Coated PVC Sheet

Coated ribbed Polycarbonate

PVC-based extrusion

MATERIALIZING DATA

The coating requires an initial Sodium Hydroxide (NaOH) solution wash, to activate the CO2 absorbing capabilities. Once saturated with CO2, the resin coating requires incremental Sodium Carbonate (Na2CO3) solution washes to unload, and transport the collected CO2 and continue absorbing thereafter. We propose a water tank located at the top of the facade panels to create an incremental washing system that leads to a designated processing station in the basement level of a building. The material system has an added component of Bromothymol blue, a pH indicator that has been used to indicate CO2, or rather, carbonic acid in water. By changing from blue to yellowish-green, the system of physical colour change can be used as an indicator to implement the washing of a saturated facade. Not only is this an indicator to unload a saturated facade, but also a method of materializing data, physically indicating the current surrounding air quality and the rate of pollution.

WASHING APPARATUS

The apparatus was created using a sealed glass box with a volume of 17.3 L. Inside holds the digital CO2 detector and a small fan for air circulation. A water pump is placed within a small acrylic tank located outside of the apparatus which holds the unloading solution. Upright within the tank is a stand holding the geometry and a collection tank underneath. A rubber tube carries the solution from the outside in and is suspended over the placed geometry. Holes located at the end of the tube release the unloading solution over the geometry to simulate the washing system of a module. This apparatus successfully tested the performance of the material system and geometry function by indicating a drop in CO2 levels and continued absorption after incremental washes.

PANEL LAYERS

The sodium carbonate solution installed at the top of the panelized facade, releases the solution, using gravity to wash the vertical waved surfaces of the interior panel walls. The seamless connection from panel to panel, allows the washing solution to continue to a collection pipe located in the bottom panels, which then leads to a basement tank. - To prevent the “water hammer” effect, the facade is vertically divided into several sections, up to 10 meters each. A pipe leads from the bottom of each section to the basement tank, where CO2-saturated solution is collected and filtered, to use a fresh solution again.

CNC rough cut

CNC finishing

Vacuum forming

Polycarbonate formed

Through the development of the Ingeo material system, we propose that our panels can aid in removing CO2 from the air. A single person exhales 0.8 - 1.1 kg of CO2 per day. One Ingeo panel absorbs approx. 0.88 kg of CO2 per day, which means a 1:1 scale panel can absorb as much CO2 as one person exhales per day. Over the course of a year, a single panel can absorb up to 320 kg of CO2.

Architectural proposal - Second skin

Interior proposal - Office division